Recently, a research team led by Professor Min Qiu at the School of Engineering of Westlake University has proposed a novel method for creating high-brightness, wide-gamut, high-resolution structural colors based on ultrafast laser-induced oxidation. This work, by constructing a Ti–TiO₂–Ti sandwich thin-film structure and employing picosecond laser to precisely control the oxidation process, achieves high-precision manipulation of the oxide layer thickness at the nanoscale. Consequently, it produces vivid, highly saturated, and finely tunable structural color displays.

Compared to traditional pigment-based coloring, this method generates color based on optical interference principles, eliminating the need for any dyes or inks, thus offering higher environmental friendliness and long-term stability. Compared to existing laser-based structural color techniques, this work achieves significant breakthroughs in key performance metrics such as brightness, color gamut, and spatial resolution.

Experimental results indicate that this structural color system can cover over 80% of the sRGB color gamut, with a maximum reflectance exceeding 60% and a spatial resolution as high as 30,000 DPI. It also demonstrates excellent resistance to corrosion, humidity, heat, and light exposure, meeting the requirements for long-term use in harsh environments. Furthermore, the method exhibits good adaptability to various substrate materials and surface roughness, enabling high-quality inkless printing on surfaces like metals and rough stainless steel. This demonstrates strong process versatility and potential for engineering applications. The fabrication strategy combines high processing efficiency, low cost, and good scalability, providing a new technological pathway for the large-scale application of structural colors in areas such as information security and anti-counterfeiting, artistic design, advertising displays, and environmental signage.

The related research findings have been published in Advanced Science under the title "High-Brightness, Wide-Gamut, and High-Resolution Structural Colors via Ultrafast Laser-Induced Oxidation of Ti/TiO₂ Thin Films". https://doi.org/10.1002/advs.202523260

Innovative Proposal of 'Metal–Dielectric–Metal' Sandwich Thin-Film Structure Enables High-Performance Laser Direct Writing of Structural Colors

Structural color is a "physical color" generated by the interaction of micro/nanostructures with light. Compared to traditional ink or dye coloring, it offers advantages such as high saturation, fade resistance, environmental friendliness, and stability, holding broad application prospects in information security, anti-counterfeiting, high-end displays, artistic creation, and decorative design. However, traditional structural color fabrication typically relies on complex and expensive nanofabrication processes, struggling to simultaneously achieve high brightness, wide color gamut, and high resolution, while also facing significant bottlenecks in processing efficiency and scalability.

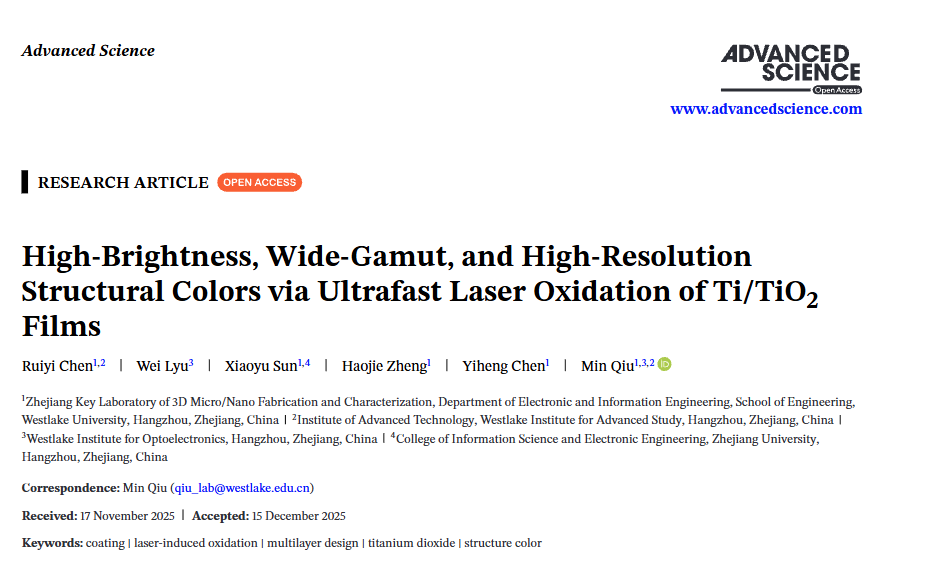

To address these challenges, the research team innovatively proposed a Ti–TiO₂–Ti sandwich multilayer thin-film structure. Combined with picosecond laser-induced controlled oxidation technology, this enables nanoscale precise control of the TiO₂ film thickness, constructing a high-performance Fabry–Pérot-like optical resonant cavity. This facilitates the laser direct writing of structural colors with high brightness, wide color gamut, and ultra-high resolution in the visible spectrum.

Figure 1. Schematic and demonstration of laser-induced coloring based on the titanium–titania–titanium sandwich structure.

Simultaneous Achievement of High Brightness, Ultra-Wide Color Gamut, and Ultra-High Resolution

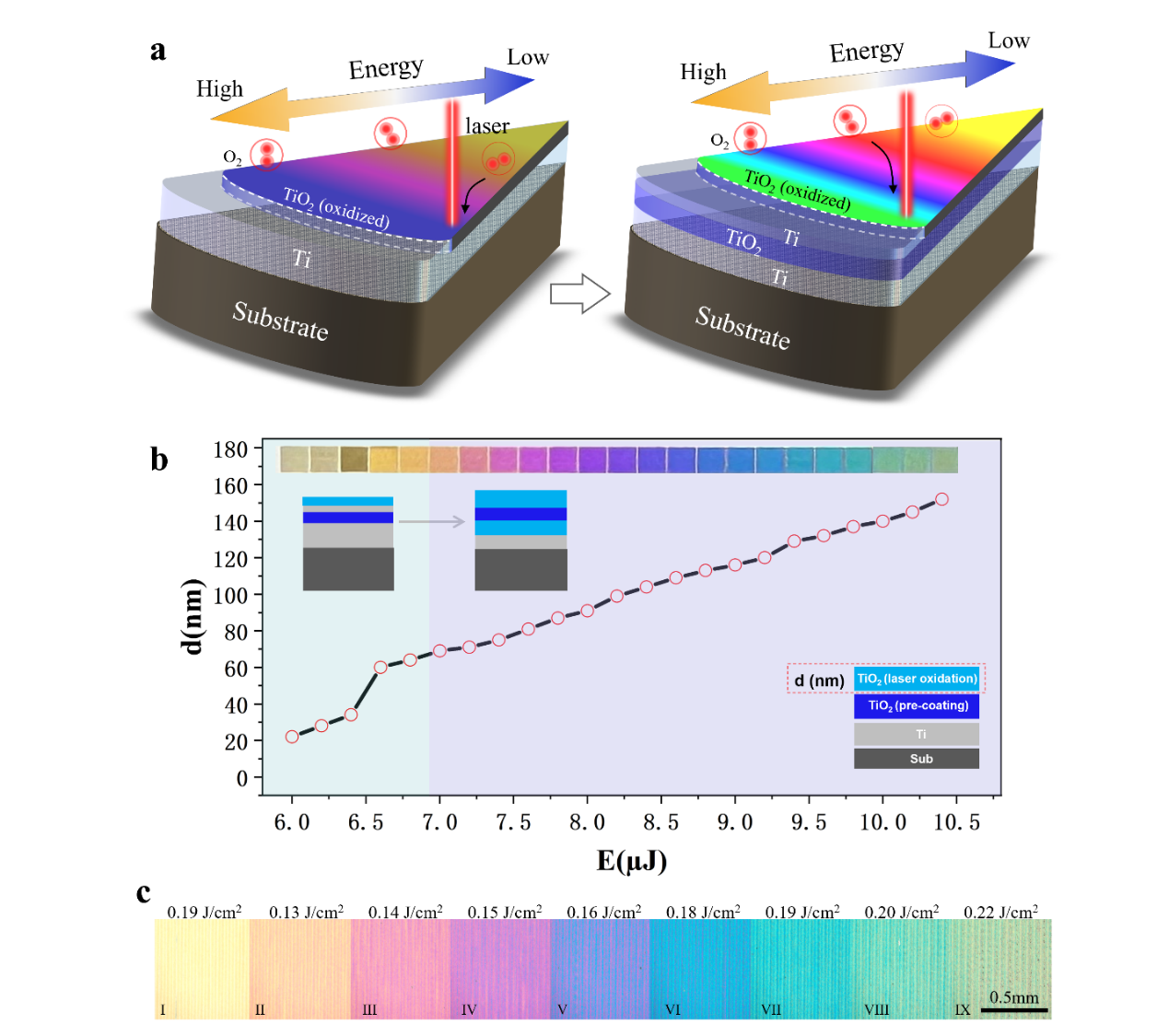

Through systematic control of thin-film structural parameters and laser energy deposition, the research team achieved multi-dimensional synergistic enhancement of structural color performance. As shown in Figure 2, by simultaneously adjusting the laser single-pulse energy, scanning speed, and initial thin-film structural parameters, the researchers achieved continuous color tuning from yellow, orange, purple, red, and blue to cyan and green within a single thin-film system. The color gamut covers about 80% of the sRGB color space in the CIE 1931 chromaticity diagram, far exceeding the ~15% gamut limitation of traditional laser oxidation methods based on bulk titanium materials. Simultaneously, the reflection spectra exhibit continuous, fine shifting characteristics, with single-step tuning precision reaching about 10 nm. The peak reflectance generally exceeds 60%, significantly enhancing color brightness and visual impact.

Figure 2. Laser-printed color image, reflection spectra, and color gamut.

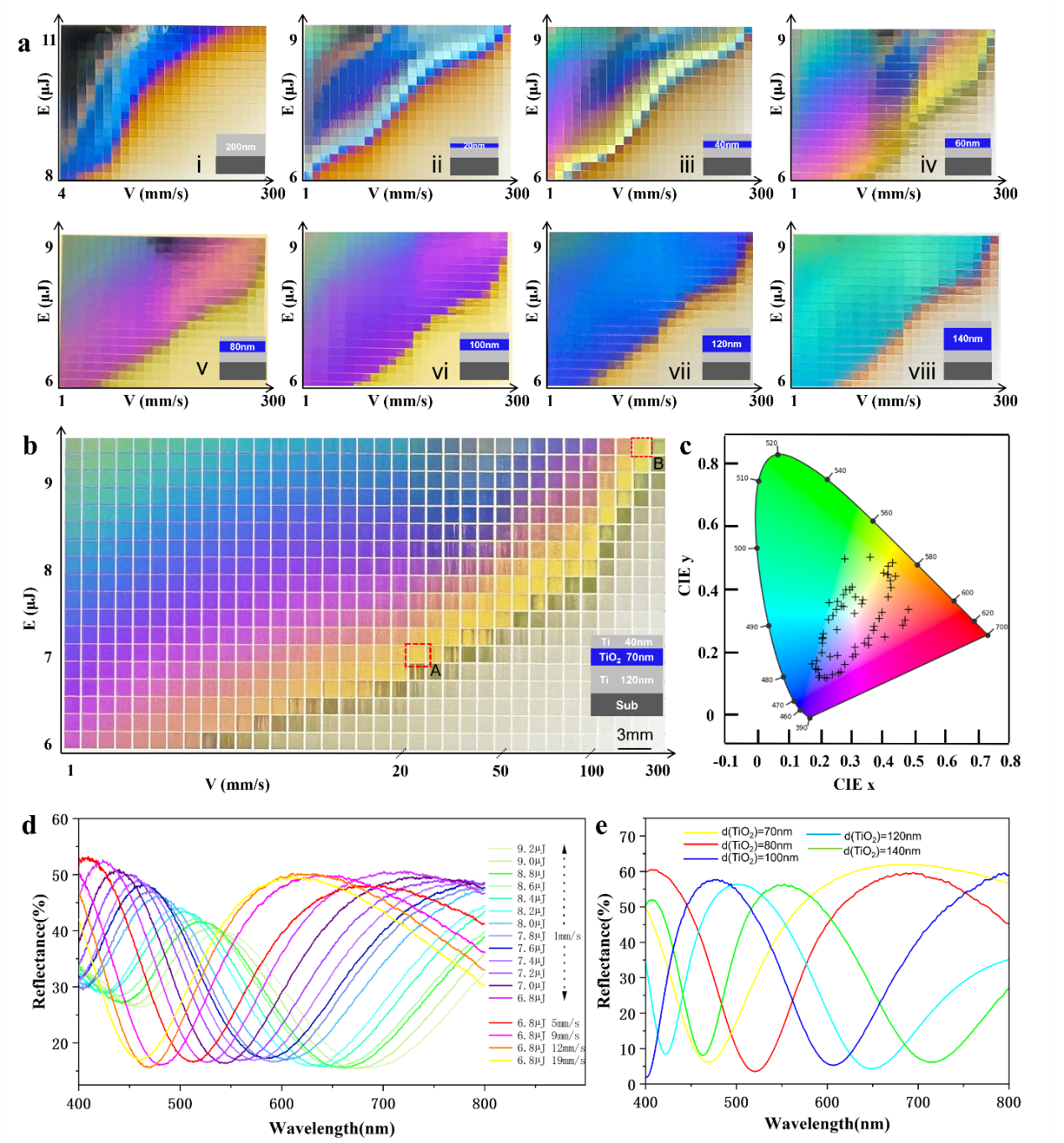

Figure 3. Cross-sectional microstructure and compositional evolution under different laser irradiation doses.

Achieving Ultra-High-Resolution 30,000 DPI Structural Color Laser Printing

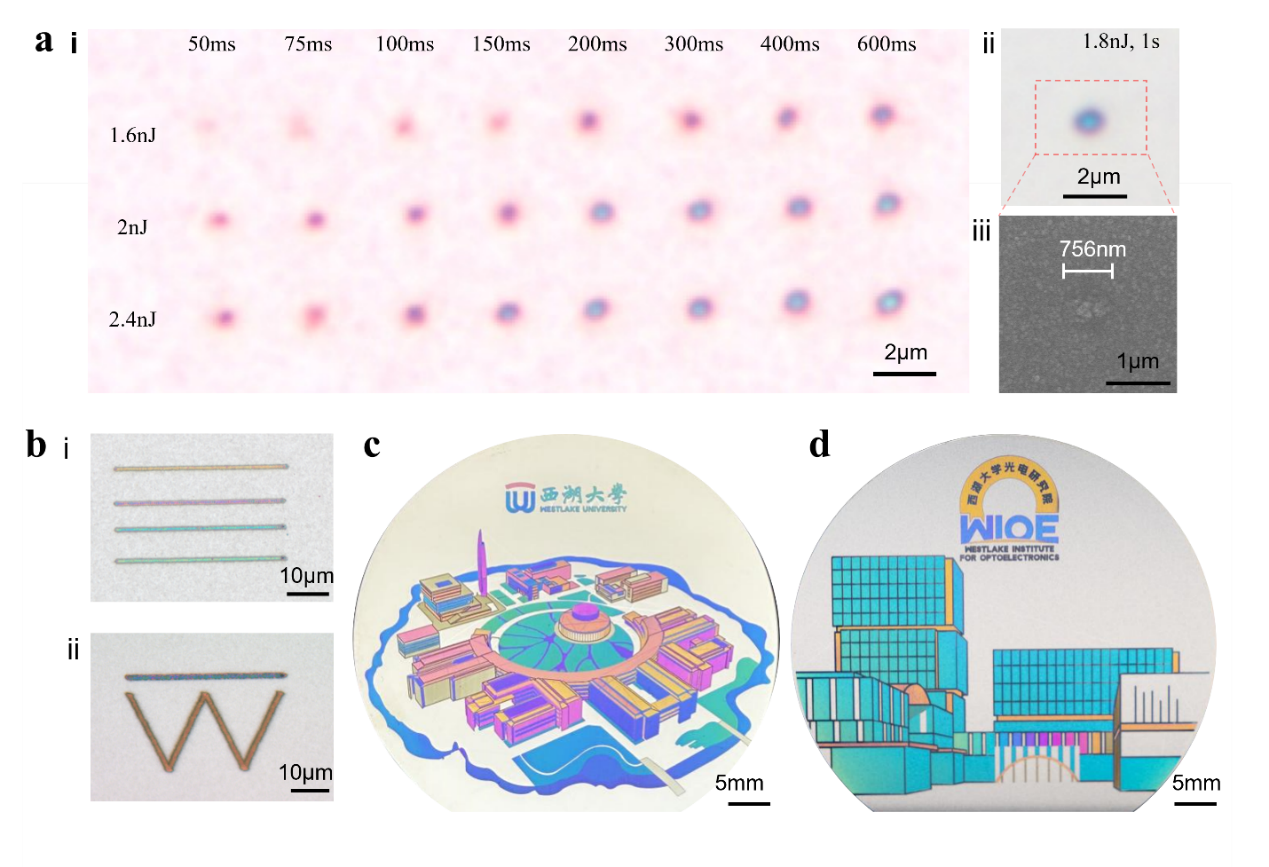

With the assistance of a high numerical aperture objective lens, the team further achieved structural color printing at the sub-micron scale. As shown in Figure 4, the researchers fabricated structural color dot arrays with diameters less than 800 nm and high-precision structural color lines with widths of about 1 µm, achieving a maximum printing resolution of 30,000 DPI. Leveraging this high-resolution capability, the team successfully performed direct laser printing of an aerial view of the Westlake University Yungu Campus and the emblem of the Institute of Optoelectronics on both polished and rough silicon wafer substrates (2-inch). This fully demonstrates the method's comprehensive capabilities in complex patterning, high-precision color printing, and large-area fabrication.

Figure 4. High-resolution laser-printed structural colors and patterns.

Excellent Stability Coupled with Broad Applicability

Beyond outstanding optical performance, the fabricated structural color thin films also passed multiple environmental reliability tests, including salt spray, humidity and heat, and condensation. They exhibit excellent corrosion resistance, abrasion resistance, and long-term stability, providing assurance for practical application in complex environments. Furthermore, the method is substrate-agnostic, enabling high-quality structural color printing on various materials such as silicon and stainless steel. It also offers advantages of high throughput and low cost, providing key technical support for the transition of structural color technology towards scalable manufacturing and engineering applications. This achievement is expected to find broad application in fields including information security, anti-counterfeiting, artistic design, high-end decoration, advertising displays, smart displays, and green printing.

Highlights of this Work:

High-Performance Structural Color Output: Based on magnetron-sputtered Ti–TiO₂–Ti sandwich films and ultrafast laser oxidation, it achieves nanoscale precise control of TiO₂ thickness, obtaining structural colors with high saturation and precisely tunable hue; color gamut >80% sRGB, reflectance >60%, maximum resolution up to 30,000 DPI.

High Durability and Reliability: The resulting thin films possess outstanding corrosion resistance, wear resistance, and stability, suitable for long-term service and complex environment applications.

Scalable Process and Substrate Independence: The thin-film deposition and laser direct writing strategy is substrate-independent, allowing flexible integration on various surfaces; it also balances high throughput, low cost, and scalable customization, targeting multi-scenario applications in information security, artistic design, advertising, and environmental technology.

Dr. Ruiyi Chen, an assistant researcher at Westlake University, is the first author of this study. Professor Min Qiu, the head of the research group, is the corresponding author.