Content writer | Lei Zhang

Title | Optical steelyard: high-resolution and wide-range refractive index sensing by synergizing Fabry–Perot interferometer with metafibers

Author |Lei Zhang, Xinggang Shang, Simin Cao , Qiannan Jia, Jiyong Wang*, Wei Yan* and Min Qiu*

The affiliations of the authors |

1 College of Information Science and Electronic Engineering, Zhejiang University, Hangzhou 310027, China.

2 Key Laboratory of 3D Micro/Nano Fabrication and Characterization of Zhejiang Province, School of Engineering, Westlake University, 18 Shilongshan RoadZhejiang Province, Hangzhou 310024, China.

3 Institute of Advanced Technology, Westlake Institute for Advanced Study, 18 Shilongshan RoadZhejiang Province, Hangzhou 310024, China.

4 Westlake Institute for Optoelectronics, Fuyang, Hangzhou 311421, China.

5 Ministry of Education Engineering Research Center of Smart Microsensors and Microsystems, School of Electronics and Information, Hangzhou Dianzi University, Hangzhou 310018, China

Research background

Optical fiber sensors have been widely studied for their light weight and real-time monitoring capabilities. Based on the area where light interacts with matter, fiber optic sensors can be categorized into side-wall integration and end-face integration. In order to adapt to the trend of device miniaturization, Fiber Tip Integrated Sensor (FTIS) has shown stronger competitive advantages, especially in complex and narrow environments. Therefore, FTIS has been applied in many fields, such as temperature/humidity detection, biomedical sensing and calibration of gas or liquid mixture concentration. In the above applications, external stimuli will cause changes in refractive index, so refractive index analysis is one of the most basic detection methods.

Generally, sensitivity, resolution and linear sensing range are three important indicators for evaluating the performance of a sensor. The sensitivity can be defined as the resonant wavelength shift caused by a unit refractive index change: S=Δλres/Δn. The resolution Figure Of Merit (FOM) is defined as the normalized sensitivity, which reflects the measurement accuracy. It is usually defined as FOM = S/FWHM. Moreover, since FWHM is related to the quality factor Q of the spectrum, i.e., FWHM = λres/Q, we have that FOM = S × Q / λres. Linear sensing range, usually related to Free Spectral Range (FSR), reflects the effective working range of a sensor. Within this range, even if the refractive index changes greatly, there is no need to perform secondary calibration on the refractive index response, thus simplifying data acquisition and processing. Ideally, people hope that FTIS has high sensitivity, high resolution and wide linear range at the same time. However, for most refractive index sensors, high resolution and wide linear range cannot be achieved simultaneously, just like the saying goes "You cannot have your cake and eat it too",

The steelyard is a macroscopic measuring tool for measuring the mass of objects, and people often use it to weigh various commodities. The steelyard has a long history, dating back to the Warring States Period. As history has evolved, the appearance of steelyards has diversified into various forms. However, they all share two essential elements: one is a set of weights used to define the measurement range, and the other is a scale bar with precise graduations. During weighing, one can first roughly estimate the mass range of the object to be measured by using weights. Then, by moving the vernier on the scale bar, balance the weight with the object to be measured, and finally read the precise value of its mass. If the rough estimation range is too small to balance the weight and the object to be measured (after traversing all scales with a vernier), you can increase the weight to expand the rough estimation range, then traverse the vernier again to read the mass of the object. The weighing process of the steelyard embodies a perfect combination of high resolution and wide linear range. If we can apply this "weight + scale" combination idea to the refractive index sensing, is it possible to achieve a sensor that simultaneously possesses a high resolution and a wide linear range?

Paper Introduction

Surface Plasmonic Resonances (SPR) can be excited on the fiber end tip when integrated with plasmonic metasurfaces. Due to the wide linear range and label-free characteristics, SPR-based FTIS has been extensively studied and applied. However, SPR typically exhibits a low sensitivity, only reaching a few hundred nm/RIU, and has a relatively low Q-factor due to the intrinsic ohmic losses. In contrast, dielectric Fabry-Perot Interferometers (FPIs) integrated on the fiber tip can support high-Q resonances, thereby providing superior resolution. Nevertheless, the operating range of FPI-type sensors is limited by their finite Free Spectral Range (FSR), resulting in a narrow range. This limitation stems from the tradeoff between the Q-factor and FSR, which are inversely proportional to each other and interrelated by the finesse (F), where F = FSR × Q/λres. Thus, once F is determined, FSR is generally inversely proportional to the cavity length, while Q is proportional to it.

Previous studies have shown that by cascading two interferometers with slightly different optical path lengths, the optical Vernier Effect can be introduced, increasing the FSR without compromising the Q-factor. However, the Vernier Effect primarily enhances sensitivity and resolution but does not fundamentally expand the operating range. Consequently, developing an FTIS that combines a high resolution and a wide linear range remains a formidable challenge.

Main Research Content

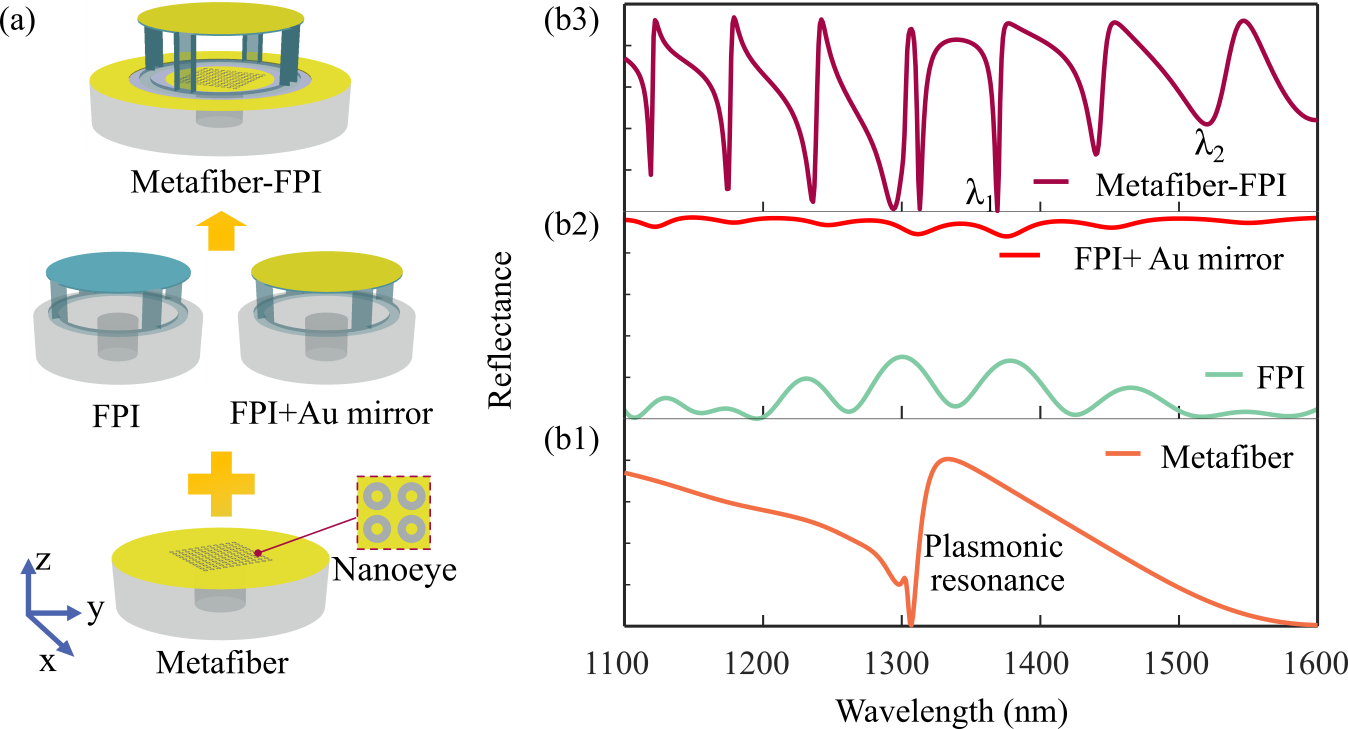

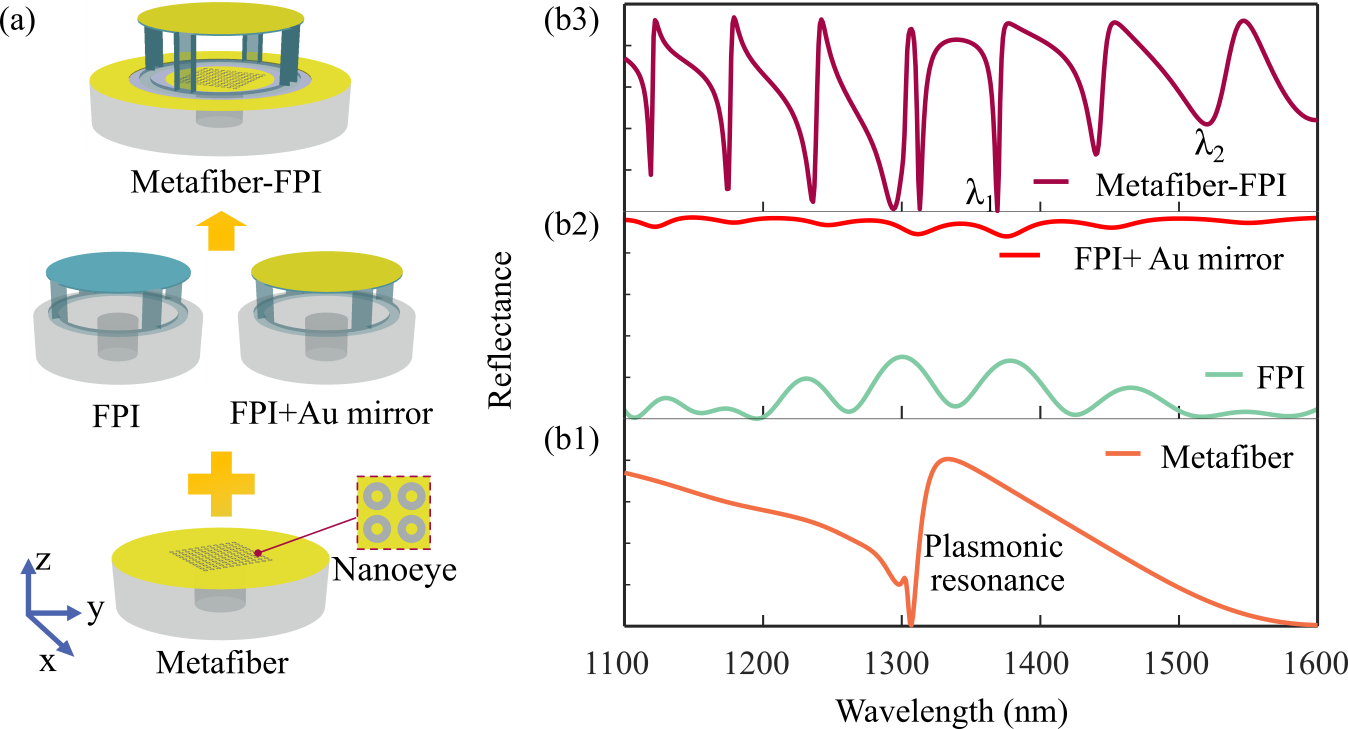

Given these considerations, this study proposes and demonstrates a high-performance FTIS. By utilizing Focused Ion Beam milling (FIB) and Two Photon Photolithography (TPL) techniques on the end face of a commercial single-mode fiber jumper, a hybrid structure comprising a two-dimensional metasurface and a three-dimensional FPI is fabricated. This hybrid structure features a hollow sandwich configuration: the bottom layer is a plasmonic metasurface, integrated on the fiber tip to form a metafiber; the middle layer is a polymer-based FPI with an open cavity; and the top layer is a uniform gold film, as illustrated in the first panel of Figure 1(a). For ease of discussion, this hybrid structure is hereafter named the metafiber-FPI. When light interacts within the metafiber-FPI, both SPR and FP resonances can be simultaneously excited.

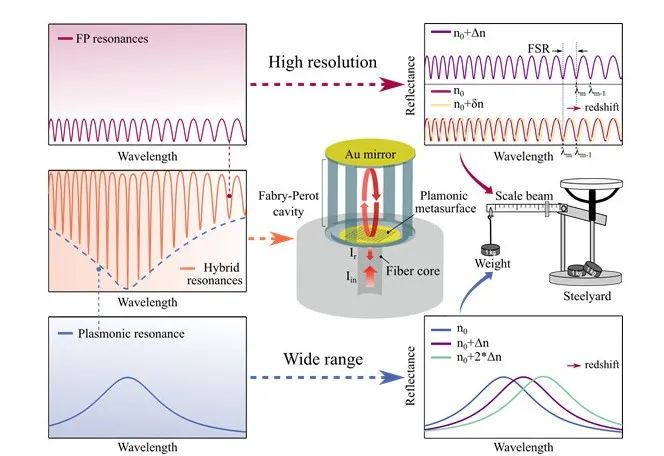

Drawing an analogy to the measurement principle of a steelyard in the macroscopic world, this study introduces the concept of an optical steelyard mechanism. The SPR resonance serves as an analogy to the weights, reflecting the refractive index range of the solution under test, while the FP resonance functions like the finely calibrated steelyard beam, providing precise values of the solution's refractive index. By synergizing the SPR resonance with a wide FSR (low Q) and the FP resonance with a high Q (narrow FSR), a sensing performance with a resolution of 2664 /RIU and a linear range exceeding a single FSR is experimentally achieved. This research was published on August 15, 2024, in PhotoniX under the title "Optical steelyard: high-resolution and wide-range refractive index sensing by synergizing Fabry–Perot interferometer with metafibers."

Technical Breakthroughs

Figure 1. Schematic illustration of the formation of the metafiber-FPI (a) and the corresponding spectral calculation of the structure (b).

1. Investigating the Mechanism behind of High Q-Factor in metafiber-FPI

As shown in Figure 1, the Q-factor enhancement in metafiber-FPI compared to conventional dielectric FPIs (green curve in b2) stems from two primary factors. Firstly, the introduction of the bottom plasmonic metasurface and the top gold film increases the reflectivity of the end face. Consequently, at the same cavity length, the finesse improves, significantly boosting the Q-factor. Secondly, the coupling of SPR and FP resonances generates a hybrid resonance with a Fano lineshape. During the formation of this hybrid resonance, the radiative loss of SPR is suppressed, further enhancing the Q-factor.

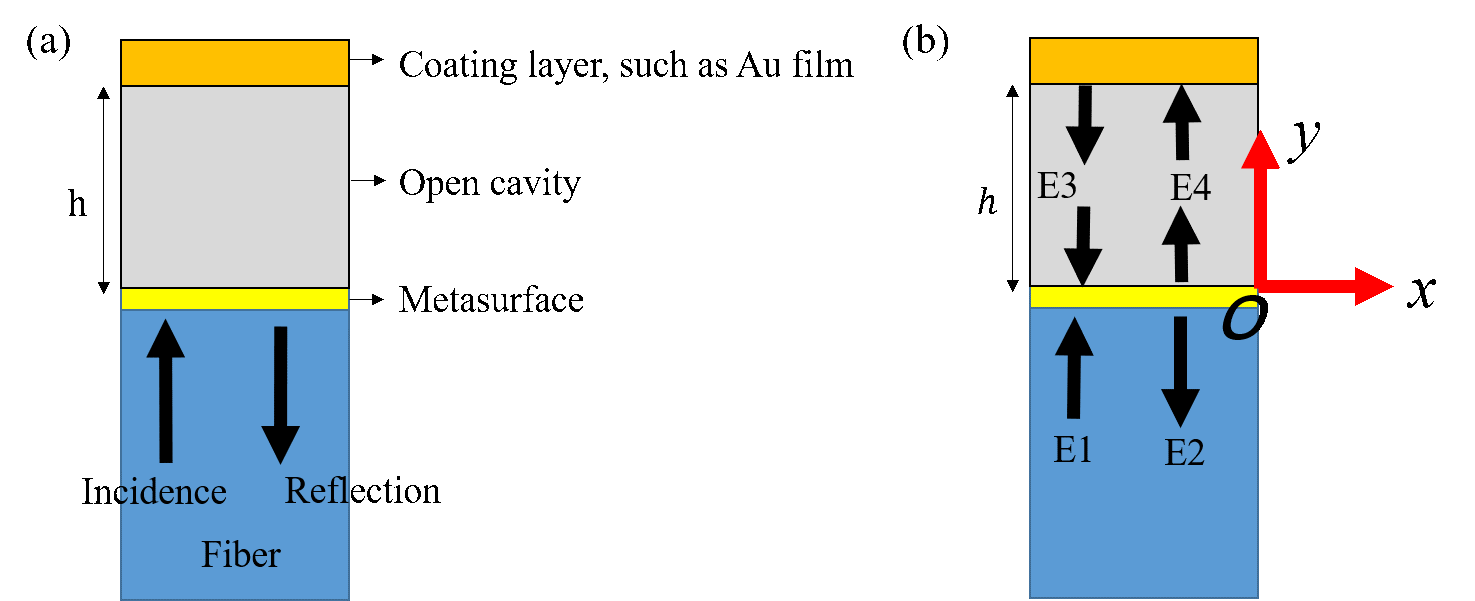

Figure 2. (a) Schematic diagram of the geometric structure of the semi-analytical model. (b) Illustration of multiple reflections in the defined coordinate system.

To delve deeper into the origin of the high-Q spectral features and efficiently solve for the reflection spectra of metafiber-FPI under different cavity lengths and dielectric environments, a semi-analytical model is built to simulate the metafiber-FPI. This model describes the physical process of light-matter interaction as multiple reflections between partially transparent nanoeye and the top gold mirror, as illustrated in Figure 2. Compared to the numerical calculations in COMSOL Multiphysics, which is often time-consuming, this model simplifies the computational process (solvable with a single line of code), providing a time-saving solution for optimizing the optical performance of metafiber-FPI.

Figure 3. Schematic diagram of the fabrication process of the metafiber-FPI, with red, blue, and green scales representing 900 nm, 38 μm, and 3.5 μm respectively.

2. Multi-dimensional Integration on the Fiber End Face

To integrate a two-dimensional metasurface and a three-dimensional resonant cavity on the end face of a single-mode fiber jumper, forming the metafiber-FPI for steelyard sensing, this study leverages the non-standard micro/nano fabrication processes on fiber end faces developed by our research group and establishes a process flow as illustrated in Figure 3.

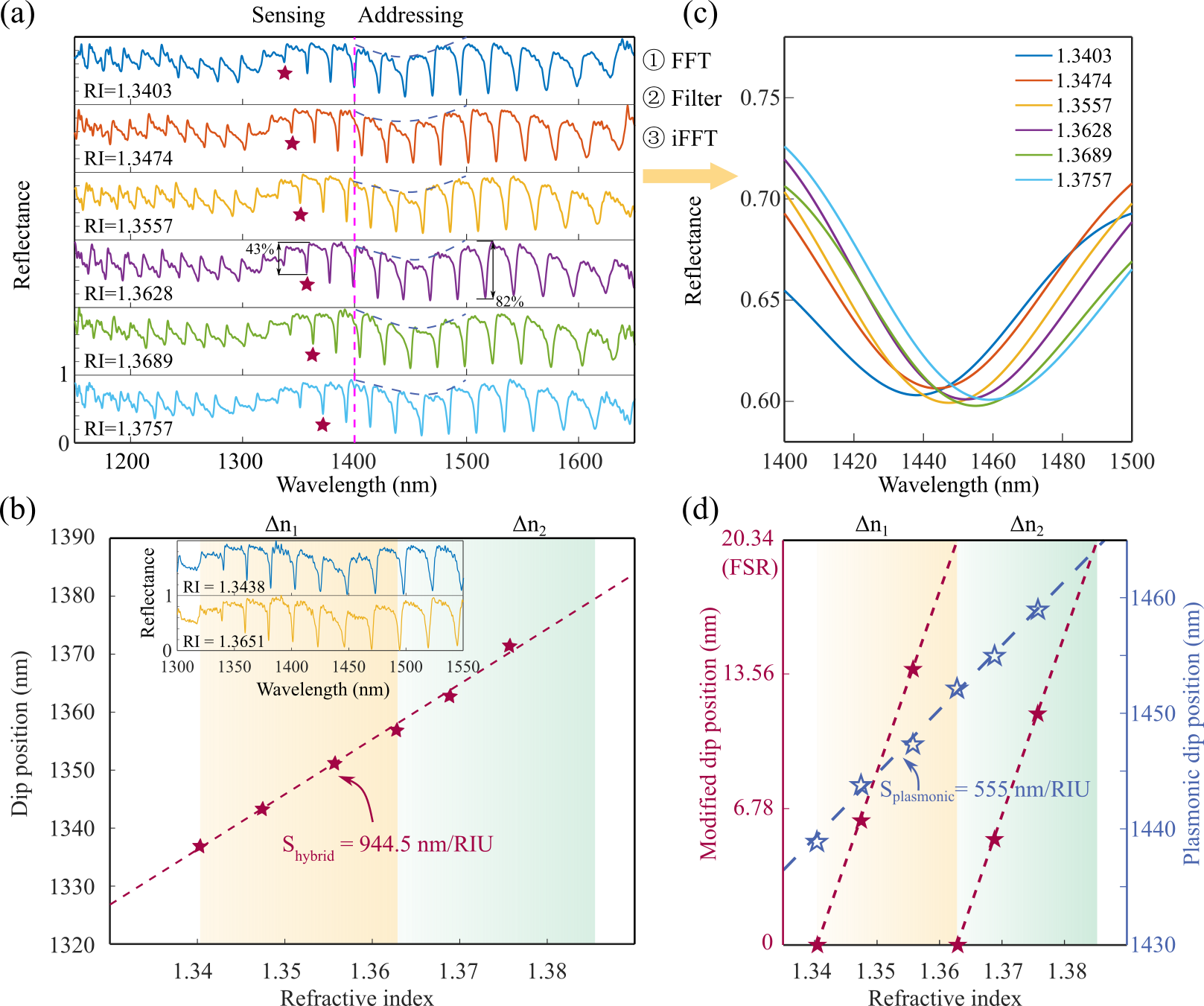

Figure 4. Fourier Analysis and Establishment of Steelyard Sensing Map. (a) Reflection spectra of the metafiber-FPI immersed in water-isopropanol mixtures. (b) Sensitivity extraction of the metafiber-FPI. (c, d) Sequential application of FFT, low-pass filtering, and iFFT to the raw data, ultimately establishing the steelyard sensing map.

3. Establishment of the Optical Steelyard Sensing Mechanism

Figure 4 demonstrates the trend of the resonance dip of the hybrid resonance varying with the refractive index of the solution. Through linear fitting of the data, it is evident that the resonance marked by the red asterisk exhibits a sensitivity of 994.9 nm/RIU. However, as shown in the blue and yellow spectra in the inset of Figure 4(b), when the spectral shift equals an FSR, the resonance dips of the hybrid resonance nearly coincide at the same wavelength within the sensing region, leading to a failure in sensing due to spectral indistinguishability. This implies that the high-resolution sensing mechanism can only effectively identify refractive index changes within a limited range, i.e., there exists an effective refractive index period Δn. To overcome the FSR limitation on the sensing range, this study employs Fourier analysis to extract the SPR component from the hybrid resonance (Figure 4(c)). Since the resonance dip of SPR exhibits a monotonic rather than periodic change with the dielectric environment, it enables the discrimination of the refractive index range (Figure 4(d)).

Perspective Commentary

Traditional FTIS face challenges in simultaneously achieving a high resolution and a wide linear sensing range. By incorporating a metafiber with an FPI with an upper gold mirror, this study presents the metafiber-FPI structure, which effectively enhances the Q-factor and broadens the FSR. Leveraging mode coupling between FP resonance and SPR, a hybrid resonance with a Fano lineshape is successfully excited, enabling the realization of a high Q-factor of approximately 3829 and a resolution of approximately 2664 nm/RIU in liquids. Furthermore, a semi-analytical model is established to analyze the physical origin of the hybrid resonance, providing deep insights into the optical properties of the coupled system and offering a rapid solution method for validating numerical results.

Through Fourier analysis, this study successfully extracts the SPR component from the hybrid resonance, resulting in a wide linear sensing range. Precise measurements are achieved in simulation and experiments over refractive index ranges of 1.330-1.430 and 1.3403-1.3757, respectively, corresponding to accurately identifying four and two FSR spectral shifts in conventional FPIs.

Lastly, the compatibility of multi-dimensional integration technology on the end face of single-mode fiber jumper is successfully demonstrated, showcasing the integration method for multi-dimensional metafibers. Meanwhile, the proposed steelyard principle offers research insights for other optical components requiring both high resolution and a wide linear range, such as on-chip spectrometers.

Source of this article

Published in: PhotoniX

Link to paper:https://photonix.springeropen.com/articles/10.1186/s43074-024-00138-3

Literature Search:PhotoniX 5, 24 (2024). https://doi.org/10.1186/s43074-024-00138-3