Spring scale is a macroscopic force meter, which is often used to weigh various fruits, vegetables, and commodities. If the size is reduced to the micro-nano scale, is it possible to calibrate and "weigh" tiny forces like a spring scale?

This requires a significant reduction in the detection limit of the sensor, placing extremely high demands on the precision of the device. In previous studies, scientists have often solved this problem by optimizing the mechanical properties of the structure itself.

Recently, Westlake University and the Hangzhou Institute of Advanced Research of the Chinese Academy of Sciences teamed up to take a different approach by optimizing the processing technology to prepare a new type of optical fiber spring sensor.

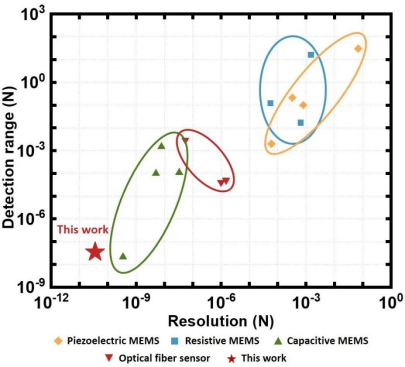

The elastic coefficient k of the optimal spring processed in this study decreased to 44.5pN/nm, with a sensitivity four orders of magnitude higher than the reported literature results, and a detection limit of 40 pico-newtons (pN, 10-12N), comparable to most microelectromechanical system devices.

The Pioneer-class fiber optic sensor is expected to open up new ideas for improving sensor accuracy and have reference value for many disciplines at the application level. For example, the scanning spring fiber optic sensor is expected to be applied in the fields of thin film Young's modulus measurement and biomechanical sensing, and the "non-contact" detection mode has application value in the fields of turbulence detection and optical force measurement.

The analysis and exploration of the preparation aspects in this study can be applied to the processing of other complex 3D structures, improving the performance of 3D structures in other application scenarios.

In addition, precise measurement of small forces is one of the important references in explaining physical phenomena at the micro-nano scale. In this study, optical fiber sensors were also applied to the field of microscopic air flow force measurement.

Thanks to the high accuracy of the sensor, the researchers captured the nonlinear variation process of airflow force near the air outlet with pressure in the experiment, which reflects the potential of high-precision mechanical sensors in sensing microscopic physical phenomena.

Qiu Min, a professor of Guoqiang Chair at Westlake University, pointed out, "We expect that the Pini-class fiber optic sensors will be applied to multidisciplinary basic research exploration. Through mechanical sensing, more and more physical phenomena may be discovered. In the future, it is expected to contribute to the exploration of basic science through precise mechanical measurements."

The reviewer commented on the study: " Min Qiu et al. have proposed an interesting study that combines nanomechanics, additive manufacturing, and photonics to achieve a picofarad-level fiber-optic end-face mechanical sensor. This study is a good example in the field of nanomechanical engineering, with important fundamental research relevance and application potential.

(Source:Advanced Materials)

Recently, a related paper titled "Fiber-Integrated Force Sensor using 3D Printed Spring-Composed Fabry-Perot Cavities with a High Precision Down to Tens of Piconewton" was published in Advanced Materials[1].

Xinggang Shang, a doctoral student at Westlake University, is the first author of the paper. Ning Wang, an associate researcher at the Hangzhou Institute for Advanced Research of the Chinese Academy of Sciences (formerly a postdoctoral fellow in Professor Min Qiu's research group), Nanjia Zhou, a distinguished researcher at Westlake University, and Min Qiu, a professor at Westlake University, are the co-corresponding authors of the paper.

How to measure tiny forces at the micro- and nanoscale?

The main difficulty in measuring tiny forces at the micro- and nanoscale lies in the simultaneous adaptation of sensing accuracy, versatility and use scenarios. For example, although microelectromechanical systems, atomic force microscopes, etc., have high precision at the pico-nano scale, they are usually developed for specific purposes, and there are problems such as high price, complicated use, limited versatility, and inability to integrate with flexible and wearable scenarios.

On the other hand, there are many technologies for measuring small deformations, such as direct imaging, capacitive, resistive, optical ranging, etc. Among them, direct imaging measurement equipment is simple and can achieve in situ real-time observation, but the measurement accuracy of this technology is limited by diffraction limits; electrical testing method has accurate signal, high sensitivity, and high detection limit, but it is easily affected by electromagnetic signal interference.

Fiber-based micro-force sensors have outstanding advantages such as flexibility, all-optical integration, and resistance to electromagnetic interference, providing new ideas for solving the above problems. Traditional fiber-optic mechanical sensors generally use fiber splicing microcavities, fiber Bragg gratings, cantilever beams, and other methods for mechanical sensing, and have been applied in many fields.

However, considering the limitations of the mechanical sensitivity of these sensing units, the accuracy is mostly in the order of nanograms, making it impossible to perform high-precision mechanical detection. The technical difficulty lies in the precision processing of high-sensitivity micro-nano 3D structures, which greatly limits the application of optical fiber sensors in the field of high-precision mechanical detection.

Min Qiu's laboratory focuses on optical devices and technology, with extensive experience in the design and preparation of optical fiber devices. In this work, they chose to face the challenges of precision design and processing of 3D fiber optic sensors, starting from optimizing the preparation process to reduce the detection limit of the sensors and solve the pain points in this field.

Let the spring scale "show its talent" on the micro-scale

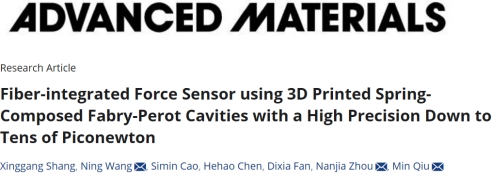

The basic principle of this research is simple, using the "interference" learned in college physics. When light passes through the interface of two media, reflection and transmission phenomena occur. This can create two optical interfaces, allowing the reflected light at the two interfaces to produce an interference superposition effect.

At this time, light of a specific wavelength "interferes destructively" and light of a specific wavelength "interferes constructively", resulting in a oscillatory spectrum. The center wavelength of the spectral valley is closely related to the spacing between the two interfaces.

When the spiral flat structure design is applied to the fiber end face, the flat and fiber end faces naturally form the two optical interfaces mentioned above, naturally forming a Fabry-Perot (FP) cavity. In the experiment, the researchers used the analysis of spectral shift to obtain the structural stress with the help of the intermediate value of structural compression.

Principle of Spring Fiber Optic Micro Force Sensor(Source:Advanced Materials)

This topic originated from a research discussion between Ning Wang and Xinggang Shang, who proposed, "Since macroscopic spring scales are so common in daily life, we also want to make it work at the microscale." After literature research, they found that some researchers have paid attention to the concept of micro-nano spring scales, but the reported device performance is far lower than other types of sensors.

To solve the problem of insufficient accuracy of optical fiber sensors, the cross-cutting topics involving optics, micro-nano mechanics, micro-nano additive manufacturing, and fluid mechanics have gradually become clearer.

Layer by Layer: Realizing High-Performance 3D-Structured Micro-Nano-Springs

After preliminary discussions and experimental explorations by the team, the researchers faced two key challenges: optimizing the preparation process and calibrating the device performance.

In terms of optimizing the preparation process, they experimentally selected the two-photon polymerization 3D processing method to prepare the spring structure. However, achieving high-performance 3D structural micro-nano springs is a great challenge. If we want to achieve better detection limits, we must meet the stringent requirements for the geometric parameters of the springs to the greatest extent possible.

However, in conventional processing processes, post-processing processes such as development and cleaning often lead to structural collapse. To address this issue, after reading a large number of literature on 3D micro-nano processing, the researchers identified the core cause of structural collapse - capillary force.

Comparison of two-photon polymerization printing results at fiber endface before and after optimization(Source:Advanced Materials)

Subsequently, after more than a year of process exploration, they improved the mechanical model of the structure's stress during liquid evaporation based on the principle and process of capillary force generation[2], and finally adopted the solution of using low surface tension cleaning agents.

Although the spring structure has existed on the original design drawings for a long time, when the members of the research team first saw the complete and stable spring under the electron microscope, they were still shocked. Min Qiu said, "This not only shows the feasibility of the entire design route, but also confirms our efforts in processing optimization for more than a year.’’

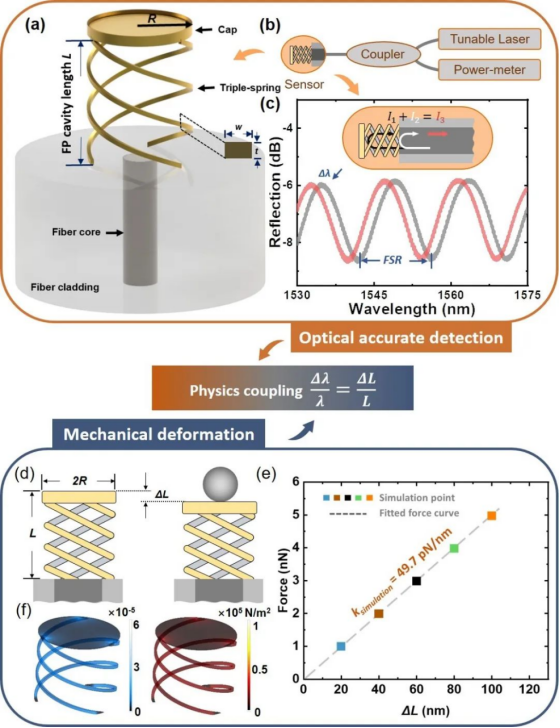

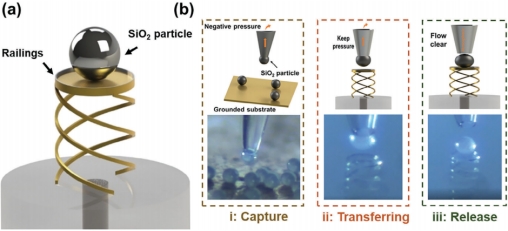

Sensor calibration by particle weight sensing(Source:Advanced Materials)

In addition, the calibration of device performance is also a major challenge. Common measurement systems are difficult to adapt to the dimensions and mechanical properties of micro-nano springs, so they adopted the method of micron particle calibration.

"We can compare the micro-nano spring to a macroscopic spring scale, in which the micron-sized particles play the role of weights on the scale. Through testing particles of different sizes, we obtained the force curve of the spring, and then analyzed the sensitivity and detection limit of the device," Xinggang Shang said.

Xinggang Shang(Source:Xinggang Shang)

With the help of Dr. Hehao Chen from Zhou Nanjia's laboratory, the researchers had a sudden idea when transferring micron particles using a micro needle: what would happen if the airflow at the needle tip was applied to the surface of the structure?

After further exploration, they found an "unexpected harvest", that is, airflow force can not only be sensed by sensors, but also there is a nonlinear variation trend between airflow force and air pressure.

"After consulting Professor Dixia Fan of Westlake University with the data, we began to try to explain the experimental phenomenon from the perspective of simulation. Eventually, the computational fluid dynamics simulation results obtained were consistent with the experiment, which well demonstrated the advantages of high-precision sensors," said Ning Wang.

Continuing to expand the application scenarios for spring sensors

The laboratory of Professor Min Qiu at Westlake University has long been engaged in basic and applied research in interdisciplinary fields, including optoelectronics, materials, energy, mechanics, chemistry, etc. The main research directions are advanced micro-nano processing technology, micro-nano photonic theory and optoelectronic devices, key optical theories and technologies, etc.

Previously, the laboratory has systematically studied the mechanical properties of micro-nano springs, exploring the relationship between the elastic coefficient and structural dimensions, as well as the stability of spring performance[3].

With the help of Professor Yunfei Jia's research group from East China University of Science and Technology, in-situ mechanical performance tests were conducted on the micro-nano springs. It was these early data that supported the idea of developing high-performance sensors.

In the early stage, by improving the process of dual-photon polymerization processing on the fiber end face and designing special fixtures for fiber adaptation, the experimental procedures were greatly simplified, and the success rate of processing was improved. Based on this processing technology, they successively developed optical fiber refractive index sensors[4] and optical fiber temperature sensors[5], accumulating relevant technical experience for this new research.

Comparison chart of the performance of various types of sensors(Source:Advanced Materials)

According to reports, the team will continue to focus on micro-nano instruments and micro-nano technology, explore the design and preparation of high-performance sensors in a deeper way, and further expand the application scenarios of optical fiber spring sensors, including designing new sensing units with better mechanical properties, developing more advanced 3D structure processing technology, and exploring better optical sensing principles.

"High-performance sensors are important tools for basic and applied research. We look forward to applying them to front-line scientific research in the future and discovering more interesting physical phenomena such as nonlinear airflow forces," Min Qiu concluded.

References:

1.Shang,X.,Wang,N. at al.Fiber-Integrated Force Sensor using 3D Printed Spring-Composed Fabry-Perot Cavities with a High Precision Down to Tens of Piconewton. Advanced Materials(2023).

https://onlinelibrary.wiley.com/doi/10.1002/adma.202305121

2.Shang,X.et al. A dual-axis mechanical model for analyzing the capillary-force-induced clustering on periodic structures. Journal of Applied Physics 134,133105(2023).

https://doi.org/10.1063/5.0165881

3.Shang,X. et al. Customizable and highly sensitive 3D micro-springs produced by two-photon polymerizations with improved post-treatment processes. Applied Physics Letters 120, 171107 (2022).

https://doi.org/10.1063/5.0088481

4.Cao,S.,Shang,X. et al. Two-photon direct laser writing of micro Fabry-Perot cavity on single-mode fiber for refractive index sensing. Optics Express 30,14,25536-25543(2023). https://doi.org/10.1364/OE.464210

5.Cao,S.,Shang,X. et al. PDMS-filled micro-spring Fabry-Perot cavity for temperature sensing. Optics Express 31,19,30332-30339(2023).

https://doi.org/10.1364/OE.498537

Article reprinted from: Liu Yakun DeepTech

Original link: https://mp.weixin.qq.com/s/jsg2_SflIG2EobOpl2iQQw