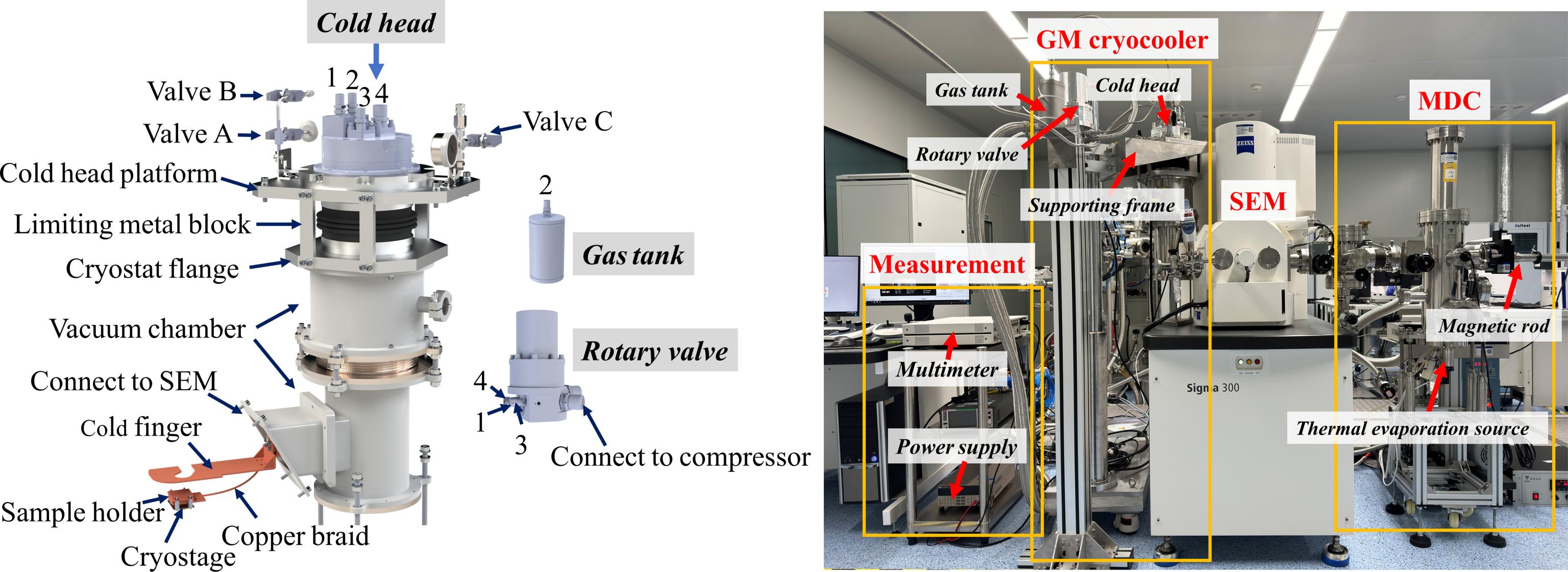

Recently, Professor Min Qiu's team from Westlake University and Professor Zhihua Gan's team from Zhejiang University successfully integrated a Gifford-McMahon cryocooler into the ice-assisted electron-beam lithography (iEBL) system, replacing the traditional liquid nitrogen (LN2) Dewar design. This innovation enables the sample stage to reach a minimum temperature of 19.14 K, successfully extending the operating temperature of the iEBL system into the liquid hydrogen temperature range.

In the iEBL system, temperature is a critical parameter that directly affects the choice and quality of precursor materials. Traditional cryogenic systems using LN2 have a theoretical minimum temperature of 77 K, which is insufficient for the freezing requirements of certain precursors, such as carbon dioxide. In the new cryogenic system, the research team successfully used carbon dioxide as a precursor in experiments, completing subsequent metal deposition and lift-off processes, thereby achieving precise micro/nano structure fabrication. Moreover, the team designed and integrated several components, including a gas-gap isolation system, to significantly reduce the mechanical vibrations introduced by the operation of the cryocooler, with the final vibration amplitude controlled to around 30 nm.

The research results have been published in the journal IEEE Transactions on Instrumentation and Measurement, titled Liquid Hydrogen Temperature Cryostage for Ice-Assisted Electron-Beam Lithography. The first author of the paper is Rui Zheng, a Ph.D. student from Professor Min Qiu's team.

Paper Link:https://ieeexplore.ieee.org/document/10739984