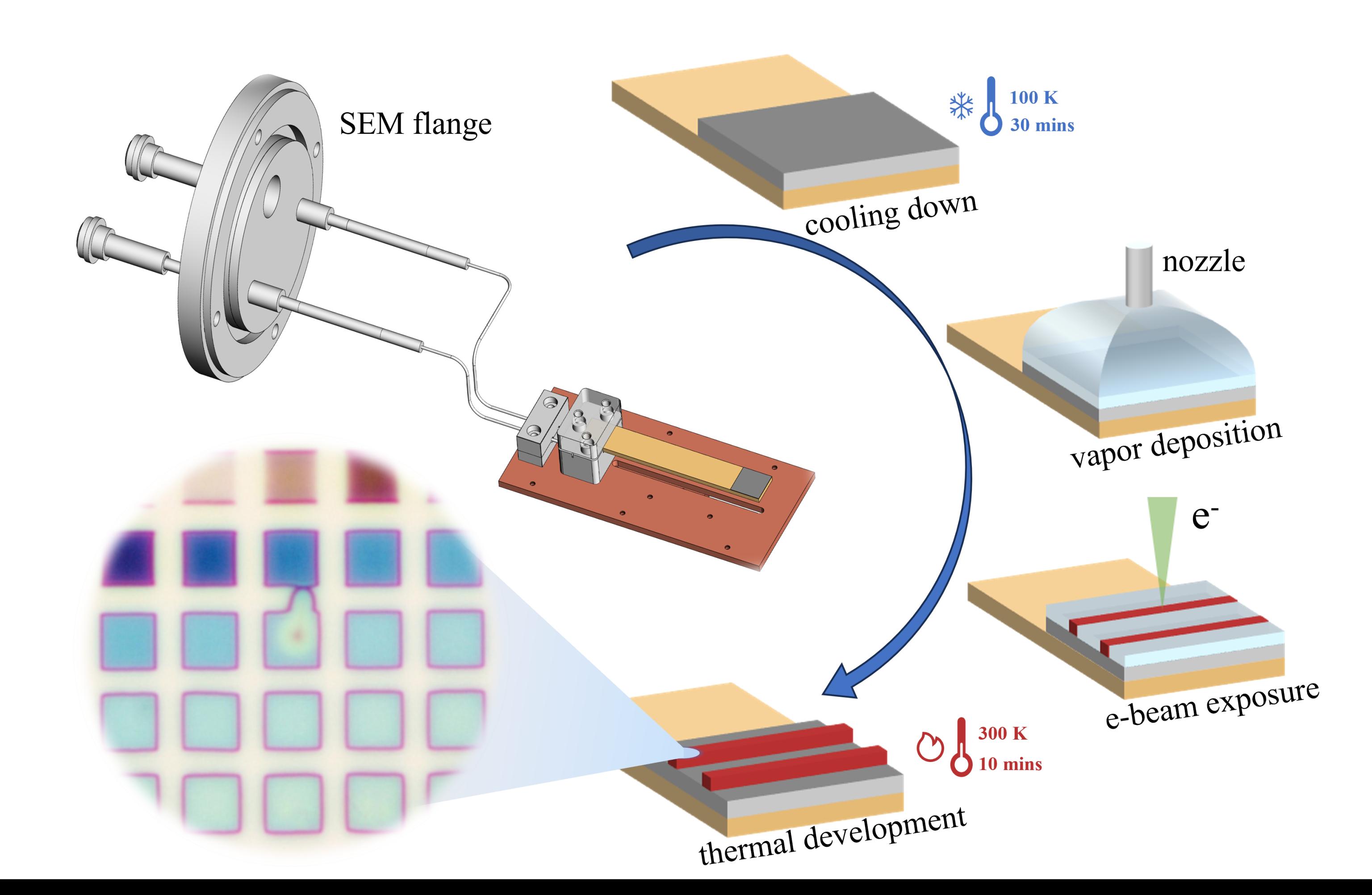

Recently, the research team led by Professor Min Qiu from Westlake University has successfully designed and tested a micromachined Joule-Thomson (JT) cryocooler, which serves as a cooling stage for ice lithography systems. This device is capable of rapidly cooling samples to 99.5 K in 30 minutes and heating them to room temperature in 10 minutes, reducing the cooling time by 90% and the operating temperature by 30 K compared to traditional ice lithography systems based on liquid nitrogen.

The cooling stage achieves low-vibration and rapid cooling through throttling and liquefaction of high-pressure nitrogen. The nitrogen mass flow rate below the sample is maintained below 20 mg/s, effectively reducing vibrations. Experiments have shown that the peak-to-peak amplitude at the lowest temperature is less than 3 nm.As the first cryocooler integrated into an ice lithography system, this cooling stage not only improves the efficiency of ice etching but also enables the exploration of a wider range of ice photoresists. The system significantly enhances the refrigeration performance, reducing the minimum line width from 61 nm to 29 nm and the minimum line spacing from 200 nm to 100 nm. In addition, the team has successfully processed a five-step structure on a 600 nm-thick solid anisole, demonstrating its ability to handle thicker ice layers.

Based on this research, Professor Min Qiu's laboratory will further reduce the cooling temperature by optimizing the microchannels and explore more advanced precursors to promote the development and application of ice lithography technology. This research has been published in the journal Microelectronic Engineering.

Paper Link: https://doi.org/10.1016/j.mee.2024.112180